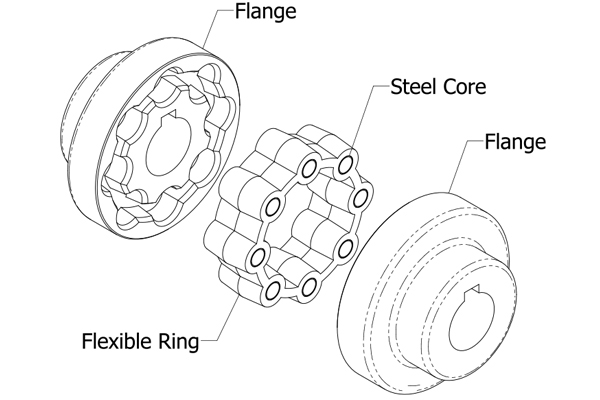

MH coupling consists of two flanges and flexible ring able to compensate all types of shaft misalignments.The flexible rings are made of synthetic rubber with steel cores reinforced for improve reliability and maximum operating speed of the coupling. The damping characteristic of the rubber anable to absorb and dampen torsional vibrations, operate effectively in temperature range of -40 to +100 °C. The rubber also resists to oil, dirt, grease, moisture, ozone and many chemical solvents.

TYPE - MH

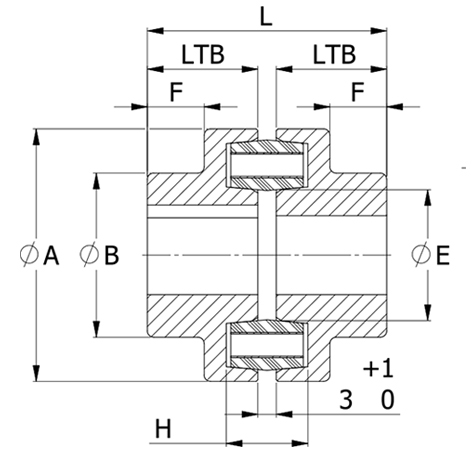

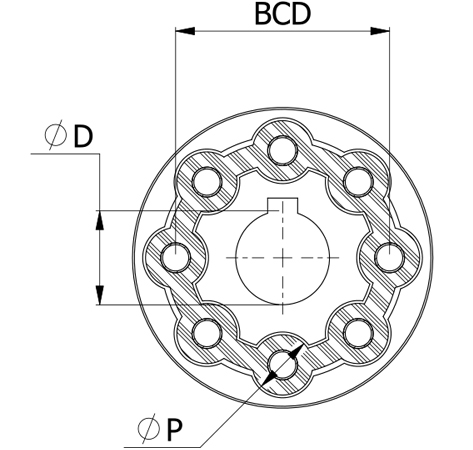

| MH Size | Rated Torque (Nm.) | Max. Speed (RPM.) | Bore, D | Dimension (mm.) | Total Weight (kg.) | Moment of Inertia GD² (kg.m²) | |||||||||

| Min. (mm.) | Max. (mm.) | A | B | LTB | L | E | F | H | BCD | P | |||||

| 45 | 2.0 | 6,000 | 5 | 14 | 45 | 25 | 23 | 49 | 20 | 13 | 15 | 30.0 | 9.5 | 0.48 | 2.10E-04 |

| 55 | 4.0 | 6,000 | 9 | 20 | 55 | 38 | 27 | 57 | 26 | 15 | 17 | 36.0 | 11.0 | 1.02 | 6.20E-04 |

| 65 | 7.0 | 6,000 | 12 | 25 | 65 | 45 | 30 | 63 | 33 | 16 | 19 | 45.0 | 12.0 | 1.88 | 1.50E-03 |

| 80 | 16.0 | 5,500 | 16 | 30 | 80 | 52 | 35 | 73 | 41 | 18 | 23 | 57.0 | 16.5 | 3.54 | 3.70E-03 |

| 90 | 37.0 | 5,000 | 20 | 35 | 90 | 62 | 40 | 83 | 46 | 21 | 25 | 64.5 | 18.0 | 5.40 | 7.10E-03 |

| 115 | 80.0 | 4,600 | 25 | 45 | 115 | 80 | 55 | 113 | 58 | 29 | 33 | 82.0 | 23.0 | 8.10 | 2.70E-02 |

| 130 | 120.0 | 4,400 | 27 | 50 | 130 | 90 | 60 | 123 | 65 | 32 | 37 | 93.5 | 27.5 | 13.50 | 4.20E-02 |

| 145 | 200.0 | 4,200 | 30 | 55 | 145 | 100 | 65 | 133 | 72 | 35 | 39 | 102.0 | 30.0 | 19.30 | 9.40E-02 |

| 175 | 420.0 | 3,800 | 35 | 65 | 175 | 115 | 80 | 163 | 84 | 43 | 47 | 120.0 | 35.5 | 26.30 | 1.90E-01 |

| 200 | 640.0 | 3,600 | 50 | 80 | 200 | 130 | 110 | 223 | 92 | 69 | 53 | 140.0 | 41.0 | 35.70 | 3.10E-01 |

Remarks:

- Accommodate shaft misalignments, parallel offset 0.2 mm. and angular 0.3°.

- Splined, hex, round, set screw or keyway bore available at additional charge.

- Coupling hub material is made of cast iron.

-

Find Rated Torque by :

Rated Torque (Nm.) = (9.55 x P x S.F.) / N

Where P = Drive rated power (kW), N = Speed (rev./min) - Select coupling with the same or higher Torque.

- Check hub bore capacity.

- Check allowable speed.