GR couplings are the three piece assembly of 2 no. Aluminium Alloy Cast Iron or Steel hubs and one Special Grade Polyurethane Spider. These three pieces are co-axially assembled to complete the GR coupling. After assembly these couplings becomes sufficient flexible, positive motion and power transmitting fail safe coupling elements. Due to polyurethane spider, both the metallic hubs are separated from each other to avoid there physical contact. This helps to avoid the electrical and frequency isolation of both the connected driver and driven elements.

Pumps, Cooling Towers, Conveyers, Rolling Mills, Hyd. Power Packs Crane, Hoist, Gear Box & Motors, Textile Machine, Special Purpose Machine And many more

Flexible, No maintenance, No Lubrication, Failsafe,Uniform & Positive motion and power transmission, Electrical and frequency isolation, Available in Unbored, pilot bore and finish bore and key-ways.

TYPE - GR

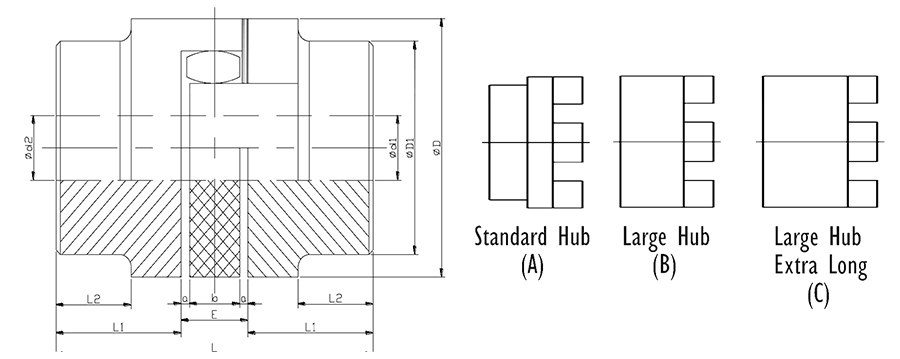

HUB DETAILS:

- GR hubs are available in Aluminium, Cast Iron and Steel Material.

- GR sizes from 19 to 28 are made from Aluminium Alloy & Steel material.

- GR sizes from 38 to 90 are made from Cast Iron & Steel Material.

- GR hubs are manufactured with high precision machining.

- The jaws are machined with concave shape and entry chamfer for easy assembly.

- The concave shape in jaws of hub and the convex shape on the polyurethane spider allows for better angular, parallel and axial misalignment.

- These hubs are available in un-bored, pilot bored, finish bore & key-ways, and with different styles of clamping arrangements as per customer requirements.

SPIDER DETAILS:

- GR spiders are manufactured from high grade polyurethane.

- GR are available in three different hardness as 64 Shore A, 92 Shore A, and 98 Shore A. This different hardness’s are made available to suit different applications.

- The details are as below.

| Spider Type | Colour | Material | Temperature Range " C | Available sizes | Application | |

| Shore Hardness | Normal working | Maximum | ||||

| 64 Shore A | Green | Polyurethane | from -50 to + 80 | from -60 to + 120 | GR 19 to 90 | More Vibration |

| 92 Shore A | Yellow | Polyurethane | from -40 to + 90 | from -50 to + 120 | GR 19 to 90 | Medium torque |

| 98 Shore A | Red | Polyurethane | from -30 to + 90 | from -40 to + 120 | GR 19 to 90 | More torque |

Dimentional Details:

| Size PUFIex GR | Bore Sizes mm Minimum Maximum | Overall Dimentions | ||||||||||||

| Outer Dia. | Hub Dia. | Spider I.D. | Total Length Std. / Large Hub | Total Length Extra Long Hub | Hub Length | Hub Length | Hub Length | Space Bet" Hubs | Spider Width | Isolation Gap | ||||

| Std. Hub | Large Hub | |||||||||||||

| dl | d2 | d2 | D | D1 | d3 | L | L | Std. L1 | Extra Long L1 | L2 | E | b | a | |

| GR 19 | 6 | 19 | 24 | 41 | 32 | 18 | 66 | 90 | 25 | 37 | 20 | 16 | 12 | 2.0 |

| GR 24 | 9 | 24 | 28 | 56 | 40 | 27 | 78 | 118 | 30 | 50 | 24 | 18 | 14 | 2.0 |

| GR 28 | 10 | 28 | 38 | 66 | 48 | 30 | 90 | 140 | 35 | 60 | 28 | 20 | 15 | 2.5 |

| GR 38 | 12 | 38 | 48 | 80 | 66 | 38 | 114 | 164 | 45 | 70 | 37 | 24 | 18 | 3.0 |

| GR 42 | 14 | 42 | 55 | 95 | 75 | 46 | 126 | 176 | 50 | 75 | 40 | 26 | 20 | 3.0 |

| GR 48 | 15 | 48 | 62 | 105 | 85 | 51 | 140 | 188 | 56 | 80 | 45 | 28 | 21 | 3.5 |

| GR 55 | 20 | 55 | 74 | 120 | 98 | 60 | 160 | 210 | 65 | 90 | 52 | 30 | 22 | 4.0 |

| GR 65 | 22 | 65 | 80 | 135 | 115 | 68 | 185 | 235 | 75 | 100 | 61 | 35 | 26 | 4.5 |

| GR 75 | 30 | 75 | 95 | 160 | 135 | 80 | 210 | 260 | 85 | 110 | 69 | 40 | 30 | 5.0 |

| GR 90 | 40 | 90 | 110 | 200 | 160 | 100 | 245 | 295 | 100 | 125 | 81 | 45 | 34 | 5.5 |

Technical Data:

| Size PUFIex GR | Rated Torque Nm | Maximum RPM | Max. Misalignment | Dynamic Torsional Stiffness 103 Nm/rad | Weight Kg | Moment of Inertia Kgm² | ||||||

| Axial mm | Radial mm | Angular Deg | ||||||||||

| 98 Sh-A | 92 Sh-A | 64 Sh-D | 98 Sh-A | 92 Sh-A 64 Sh-D | ||||||||

| GR 19 | 17 | 10 | 21 | 16700 | 1,2 | 0.2 | 1.2 | 2.92 | 1.28 | 5.35 | 0.51 | 0.000121 |

| GR 24 | 60 | 35 | 75 | 12100 | 1.4 | 0.22 | 0.9 | 9.93 | 4.86 | 15.11 | 1.10 | 0.000466 |

| GR 28 | 160 | 95 | 200 | 10100 | 1.5 | 0.25 | 0.9 | 26.77 | 10.90 | 27.52 | 1.80 | 0.00107 |

| GR 38 | 325 | 190 | 405 | 8300 | 1.8 | 0.28 | 1.0 | 48.57 | 21.05 | 70.15 | 2.50 | 0.00171 |

| GR 42 | 450 | 265 | 560 | 7000 | 2.0 | 0.32 | 1.0 | 54.50 | 23.74 | 79.86 | 3.90 | 0.00476 |

| GR 48 | 525 | 310 | 655 | 6350 | 2.1 | 0.36 | 1.1 | 65.29 | 36.70 | 95.51 | 5.30 | 0.00805 |

| GR 55 | 685 | 410 | 825 | 5500 | 2.2 | 0.38 | 1.1 | 94.97 | 50.72 | 107.92 | 7.90 | 0.01564 |

| GR 65 | 940 | 625 | 1175 | 4950 | 2.6 | 0.42 | 1.2 | 129.51 | 97.13 | 151.09 | 11.90 | 0.03071 |

| GR 75 | 1920 | 1280 | 2400 | 4150 | 3.0 | 0.48 | 1.2 | 197.50 | 113.32 | 248.22 | 18.60 | 0.06706 |

| GR 90 | 3600 | 2400 | 4500 | 3300 | 3.4 | 0.5 | 1.2 | 312.20 | 190.09 | 674.52 | 33.60 | 0.22139 |

GS Couplings are the three piece assembly of 2 no. Aluminium Alloy or Steel hubs and one Special Grade Polyurethane Spider. These three pieces are co-axially and with certain positive pre-stress are assembled to complete the coupling. After assembly these couplings becomes sufficient flexible, backlash-free, positive motion and power transmitting fail safe coupling elements. Due to polyurethane spider, both the metallic hubs are separated from each other to avoid there physical contact. This helps to avoid the electrical and frequency isolation of both the connected driver and driven elements.

Shaft Encoders, Tacho-generators, Servo Motors, Stepper Motors, Ball-screws, CNC machines, X-V slides, Medical Equipment's, Precise Spindles, and much more precise backlash-free motion and power transmission applications.

Flexible, Backlash-free, No maintenance, No Lubrication, Failsafe,Uniform & Positive motion and power transmission, Electrical and frequency isolation, Available in Unbored, pilot bore and finish bore and key-ways.

TYPE - GS

HUB DETAILS:

- GS hubs are available in Aluminium and Steel Material.

- GS sizes from 9 to 38 are made from Aluminium Alloy material.

- GS sizes from 42 to 65 are made from Steel.

- Hubs are manufactured with high precision machining.

- The jaws are machined with concave shape and entry chamfer for easy assembly.

- The concave shape in jaws of hub and the convex shape on the polyurethane spider allows for better angular, parallel and axial misalignment.

- These hubs are available in un-bored, pilot bored, finish bore & key-ways, and with different styles of clamping arrangements as per customer requirements.

SPIDER DETAILS:

- GS spiders are manufactured from high grade polyurethane.

- GS are available in three different hardness as 80 Shore A, 92 Shore A, and 98 Shore A. This different hardness's are made available to suit different applications.

- The details are as below.

| Spider Type | Colour | Material | Temperature Range ° C | Available sizes | Application | |

| Shore Hardness | Normal working | Maximum | ||||

| 80 Shore A | Blue | Polyurethane | from -50 to + 80 | from -60 to + 120 | PUFIex 5 to 24 | Low torque, more mis-alignment |

| 92 Shore A | Yellow | Polyurethane | from -40 to + 90 | from -50 to + 120 | PUFIex 5 to 55 | Medium torque, medium mis-alignment |

| 98 Shore A | Red | Polyurethane | from -30 to + 90 | from -40 to + 120 | PUFIex 5 to 55 | More torque, less mis-alignment |

Dimentional Details:

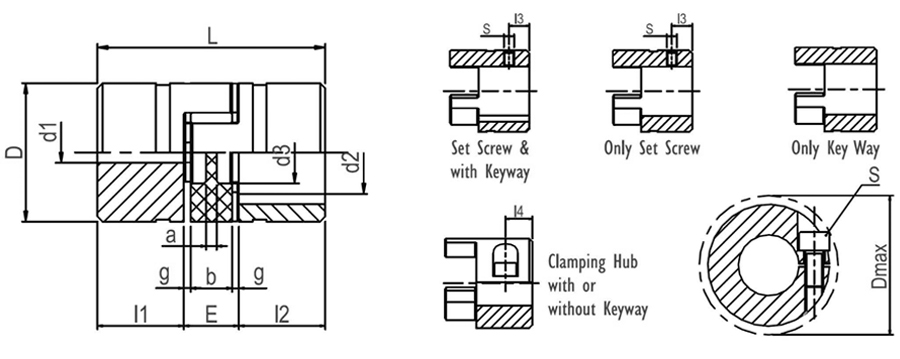

| Size PUFIex | Bore Sizes mm | Overall Dimentions | Set Screw Type | Clamping Hub Type | Screw | ||||||||||||

| Minimum Maximum | Outer | Spider | Total | Hub | Space Bet" | Spider | Isolation | Spider Wall | Screw | Distance | Screw | Distance | Max. | Tightening | |||

| Set Screw | Clamping | Dia. | I.D. | Length | Length | Hubs | Width | Gap | Thickness | Size | from edge | Size | from edge | Dia. | Torque | ||

| dl | d2 | d2 | D | d3 | L | I1 &I2 | E | b | g | a | S | I3 | S | I4 | Dmax | Ts Nm | |

| GS 9 | 4 | 11 | 9 | 20 | 7 | 30 | 10 | 10 | 8 | 1 | 1.5 | M4 | 5 | M3 | 5 | 23.4 | 1.5 |

| GS 14 | 6 | 16 | 14 | 30 | 10.5 | 35 | 11 | 13 | 10 | 1.5 | 2 | M4 | 5 | M3 | 5 | 32.2 | 1.5 |

| GS 19/24 | 6 | 24 | 24 | 40 | 18 | 66 | 25 | 16 | 12 | 2 | 3 | M5 | 10 | M6 | 12 | 45.5 | 10.5 |

| GS 24/28 | 8 | 28 | 28 | 55 | 27 | 75 | 30 | 18 | 14 | 2 | 3 | M5 | 10 | M6 | 12 | 56.4 | 10.5 |

| GS 28/38 | 10 | 38 | 38 | 65 | 30 | 90 | 35 | 20 | 15 | 2.5 | 4 | M6 | 15 | M8 | 14 | 72.6 | 10.5 |

| GS 38/45 | 12 | 45 | 45 | 80 | 38 | 114 | 45 | 24 | 18 | 3 | 4 | M8 | 15 | M8 | 20 | 83.3 | 25 |

| GS 42 | 14 | 55 | X | 95 | 46 | 126 | 50 | 26 | 20 | 3 | 4 | M8 | 20 | M8 | 20 | 79 | 25 |

| GS 48 | 15 | 62 | X | 105 | 51 | 140 | 56 | 32 | 28 | 3.5 | 4 | M8 | 20 | M10 | 22 | 91 | 70 |

| GS55 | 20 | 70 | X | 120 | 60 | 160 | 65 | 30 | 22 | 4 | 4.5 | M10 | 20 | M12 | 25 | 105 | 120 |

Technical Data:

| Size | Spider | Rated | Max RPM | Dynamic Torsional | Radial | Weight | Moment of | |

| Hardness | Torque | Set Screw | Clamping Hub | Stiffness | Stiffness | Inertia | ||

| Nm | N m/ rad | N/mm | Kg | Kgcm2 | ||||

| GS 9 | 80 Shore A | 1.8 | 28000 | 22500 | 52 | 125 | 0.019 | 0.011 |

| GS 9 | 92 Shore A | 3 | 28000 | 22500 | 95 | 262 | 0.019 | 0.011 |

| GS 9 | 98 Shore A | 5 | 28000 | 22500 | 155 | 518 | 0.019 | 0.011 |

| GS 14 | 80 Shore A | 4 | 15900 | 12700 | 180 | 153 | 0.05 | 0.062 |

| GS 14 | 92 Shore A | 7.5 | 15900 | 12700 | 344 | 336 | 0.05 | 0.062 |

| GS 14 | 98 Shore A | 12.5 | 15900 | 12700 | 513 | 604 | 0.05 | 0.062 |

| GS 19/24 | 80 Shore A | 4.9 | 11900 | 9550 | 1030 | 582 | 0.16 | 0.39 |

| GS 19/24 | 92 Shore A | 10 | 11900 | 9550 | 1720 | 1120 | 0.16 | 0.39 |

| GS 19/24 | 98 Shore A | 17 | 11900 | 9550 | 2580 | 2010 | 0.16 | 0.39 |

| GS24/28 | 92 Shore A | 35 | 8850 | 6950 | 4296 | 1480 | 0.33 | 1.60 |

| GS24/28 | 98 Shore A | 60 | 8850 | 6950 | 6189 | 2560 | 0.33 | 1.60 |

| GS 28/38 | 92 Shore A | 95 | 7350 | 5850 | 6876 | 1780 | 0.56 | 3.80 |

| GS 28/38 | 98 Shore A | 160 | 7350 | 5850 | 10314 | 3200 | 0.56 | 3.80 |

| GS 38/45 | 92 Shore A | 190 | 5950 | 4750 | 13752 | 2350 | 1.10 | 10.00 |

| GS 38/45 | 98 Shore A | 325 | 5950 | 4750 | 21486 | 4400 | 1.10 | 10.00 |

| GS 42 | 92 Shore A | 265 | 5000 | 4000 | 14490 | 2430 | 1.85 | 22.50 |

| GS 42 | 98 Shore A | 450 | 5000 | 4000 | 48000 | 5570 | 1.85 | 22.50 |

| GS48 | 92 Shore A | 310 | 4550 | 3600 | 18055 | 2580 | 2.50 | 46.00 |

| GS48 | 98 Shore A | 525 | 4550 | 3600 | 55925 | 5930 | 2.50 | 46.00 |

| GS 55 | 92 Shore A | 410 | 3950 | 3150 | 21850 | 2980 | 4.10 | 85.25 |

| GS 55 | 98 Shore A | 685 | 3950 | 3150 | 59500 | 6686 | 4.10 | 85.25 |