Globally accepted by all engineering sectors for its unique shock absorbing and detuning properties, Resilient Couplings have earned the reputation of being ideal for drives where trouble-free operation is essential. The coupling acts as a mechanical fuse for the drive system, helps in altering the torsional vibration frequency, and prevents build up of resonance in the system. Ranging from various applications in Industries like power, steel, sugar, paper, mines, chemical, etc., where reliability is of paramount importance.

Product Description

Globally accepted by all engineering sectors for its unique shock absorbing and detuning properties, Resilient Couplings have earned the reputation of being ideal for drives where trouble-free operation is essential. The coupling acts as a mechanical fuse for the drive system, helps in altering the torsional vibration frequency, and prevents build up of resonance in the system. Ranging from various applications in Industries like power, steel, sugar, paper, mines, chemical, etc., where reliability is of paramount importance.

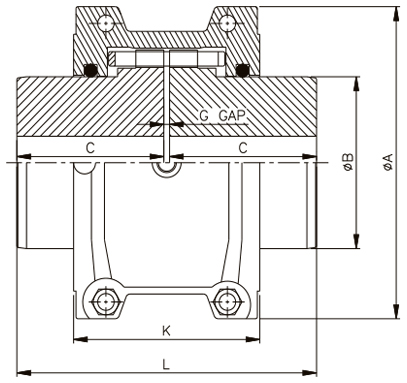

BVRG Coupling

TYPE - BVRG

| Coupling Size |

KW at 100 rpm |

Basic Torque (Nm) |

Max. Speed (rpm) |

Bore Dia (mm) | Dimensions (mm) | Gap (mm) |

Lube weight (Kg) |

Weight In (kg) |

|||||

| Min. | Max. | ØA | Ø B | C | K | L | |||||||

| 1020 | 0.50 | 48 | 4500 | 13.0 | 30 | 101.5 | 39.7 | 47.5 | 66.5 | 98.0 | 3 | 0.03 | 1.9 |

| 1030 | 1.42 | 136 | 4500 | 13.0 | 36 | 110.0 | 49.2 | 47.5 | 68.0 | 98.0 | 3 | 0.03 | 2.6 |

| 1040 | 2.36 | 226 | 4500 | 13.0 | 44 | 117.5 | 57.1 | 51.0 | 70.0 | 104.5 | 3 | 0.05 | 3.4 |

| 1050 | 4.14 | 395 | 4500 | 13,0 | 51 | 138.0 | 66.7 | 60.0 | 79,5 | 123.5 | 3 | 0.05 | 5.4 |

| 1060 | 6.50 | 621 | 4350 | 19.5 | 57 | 150.5 | 76.2 | 63.5 | 92.0 | 130.0 | 3 | 0.09 | 7.3 |

| 1070 | 9.46 | 903 | 4125 | 19.5 | 68 | 162.0 | 87.3 | 76.0 | 95.0 | 155.5 | 3 | 0.11 | 10 |

| 1080 | 19.51 | 1863 | 3600 | 27.0 | 82 | 194.0 | 104.8 | 89.0 | 116.0 | 181.0 | 3 | 0.17 | 18 |

| 1090 | 35.47 | 3387 | 3600 | 27.0 | 95 | 213.0 | 123.8 | 98.5 | 122.0 | 200.0 | 3 | 0.25 | 25 |

| 1100 | 59.71 | 5702 | 2400 | 41.5 | 110 | 250.0 | 142.0 | 120.5 | 155.5 | 245.5 | 4.5 | 0.43 | 42 |

| 1110 | 88.67 | 8468 | 2250 | 41.5 | 120 | 270.0 | 160.3 | 127.0 | 161.5 | 258.5 | 4.5 | 0.51 | 54 |

| 1120 | 130.05 | 12420 | 2025 | 60.5 | 140 | 308.0 | 179.4 | 149.5 | 191.5 | 304.5 | 6 | 0.73 | 81 |

| 1130 | 189.17 | 18066 | 1800 | 66.5 | 170 | 346.0 | 217.5 | 162.0 | 195.0 | 330.0 | 6 | 0.91 | 121 |

| 1140 | 271.93 | 25969 | 1650 | 66.5 | 200 | 384.0 | 254.0 | 183.0 | 201.0 | 371.5 | 6 | 1.13 | 178 |

| 1150 | 378.34 | 36131 | 1500 | 108.0 | 215 | 453.0 | 269.2 | 183.0 | 271.0 | 372.0 | 6 | 1.95 | 234 |

| 1160 | 532.04 | 50810 | 1350 | 120.5 | 240 | 501.5 | 304.8 | 198.0 | 279.0 | 402.0 | 6 | 2.81 | 317 |

| 1170 | 709.38 | 67746 | 1225 | 133.5 | 280 | 566.5 | 355.6 | 216.0 | 304.0 | 438.0 | 6 | 3.49 | 448 |

| 1180 | 983.68 | 93941 | 1100 | 152.5 | 300 | 630.0 | 393.7 | 239.0 | 321.0 | 483.5 | 6 | 3.76 | 619 |

| 1190 | 1300.53 | 124201 | 1050 | 152.5 | 335 | 675.5 | 436.9 | 259.0 | 325.0 | 524.5 | 6 | 4.40 | 776 |

| 1200 | 1773.46 | 169365 | 900 | 179.0 | 360 | 757.0 | 497.8 | 279.5 | 355.5 | 565.0 | 6 | 5.62 | 1058 |

| 1210 | 2605.47 | 248822 | 820 | 178.0 | 390 | 844.5 | 533.4 | 305.0 | 432.0 | 622.5 | 12.7 | 10.5 | 1424 |

| 1220 | 3515.89 | 335768 | 730 | 203.0 | 420 | 920.5 | 571.5 | 325.1 | 490.0 | 663.0 | 12.7 | 16.1 | 1785 |

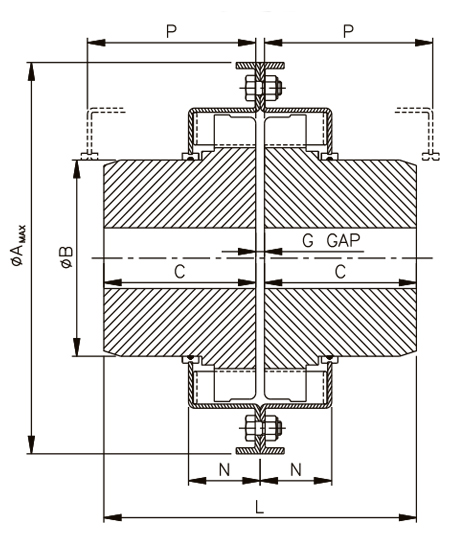

BVRV Coupling

TYPE BVRV

| Coupling Size |

KW at 100 RPM |

Basic Torque (Nm) |

Max. Speed (rpm) |

Bore Dia (mm) | Dimensions (mm) | Gap (mm) | Lube weight (Kg) |

Weight In (kg) |

||||||

| Min. | Max. | ØA | ØB | C | L | N | P | |||||||

| 1020 | 0.50 | 48 | 6000 | 13.0 | 30 | 111.0 | 39.7 | 47.5 | 98.0 | 24.0 | 47.5 | 3 | 0.03 | 2.0 |

| 1030 | 1.40 | 134 | 6000 | 13.0 | 36 | 121.0 | 49.2 | 47.5 | 98.0 | 25.0 | 47.5 | 3 | 0.03 | 2.6 |

| 1040 | 2.30 | 219 | 6000 | 13.0 | 44 | 128.5 | 57.1 | 51.0 | 104.5 | 25.5 | 51.0 | 3 | 0.05 | 3.4 |

| 1050 | 4.10 | 391 | 6000 | 13.0 | 51 | 147.5 | 66.7 | 60.5 | 123.5 | 31.0 | 60.5 | 3 | 0.05 | 5.4 |

| 1060 | 6.49 | 620 | 6000 | 19.0 | 57 | 162.0 | 76.2 | 63.5 | 130.0 | 32.0 | 63.5 | 3 | 0.09 | 7.3 |

| 1070 | 9.39 | 897 | 5500 | 19.0 | 68 | 173.0 | 87.3 | 76.0 | 155.5 | 33.5 | 76.0 | 3 | 0.11 | 10.4 |

| 1080 | 19.48 | 1860 | 4750 | 27.0 | 82 | 200.0 | 104.8 | 89.0 | 181.0 | 44.0 | 89.0 | 3 | 0.17 | 17.7 |

| 1090 | 34.96 | 3339 | 4000 | 27.0 | 95 | 232.0 | 123.8 | 98.5 | 200.0 | 47.5 | 98.5 | 3 | 0.25 | 25.4 |

| 1100 | 59.44 | 5676 | 3250 | 41.5 | 110 | 267.0 | 142.0 | 120.5 | 245.5 | 60.0 | 120.5 | 4.5 | 0.43 | 42.2 |

| 1110 | 87.90 | 8395 | 3000 | 41.5 | 120 | 286.0 | 160.3 | 127.0 | 258.5 | 64.0 | 127.0 | 4.5 | 0.51 | 54.4 |

| 1120 | 129.86 | 12401 | 2700 | 60.5 | 140 | 319.0 | 179.4 | 149.0 | 304.5 | 73.5 | 149.0 | 6 | 0.73 | 81.6 |

| 1130 | 188.79 | 18030 | 2400 | 67.0 | 170 | 378.0 | 217.5 | 162.0 | 330.0 | 75.0 | 162.0 | 6 | 0.91 | 122.5 |

| 1140 | 271.70 | 25948 | 2200 | 67.0 | 200 | 416.0 | 254.0 | 183.0 | 371.5 | 78.0 | 183.0 | 6 | 1.13 | 180.1 |

| 1150 | 378.59 | 36155 | 2000 | 108.0 | 215 | 476.5 | 269.2 | 183.0 | 372.0 | 107.0 | 183.0 | 6 | 1.95 | 230.0 |

| 1160 | 532.04 | 50810 | 1750 | 121.0 | 240 | 533.5 | 304.8 | 198.0 | 402.0 | 114.5 | 198.0 | 6 | 2.81 | 321.1 |

| 1170 | 709.38 | 67746 | 1600 | 133.5 | 280 | 584.0 | 355.6 | 216.0 | 438.0 | 120.0 | 216.0 | 6 | 3.49 | 448.2 |

| 1180 | 983.68 | 93941 | 1400 | 152.5 | 300 | 630.0 | 393.7 | 239.0 | 483.5 | 130.0 | 239.0 | 6 | 3.76 | 591.0 |

| 1190 | 1300.53 | 124201 | 1300 | 152.5 | 335 | 685.0 | 436.9 | 260.0 | 524.0 | 135.0 | 259.0 | 6 | 4.40 | 761.0 |

| 1200 | 1773.46 | 169365 | 1100 | 178.0 | 360 | 737.0 | 497.8 | 279.5 | 565.0 | 145.0 | 279.5 | 6 | 5.62 | 1021.0 |

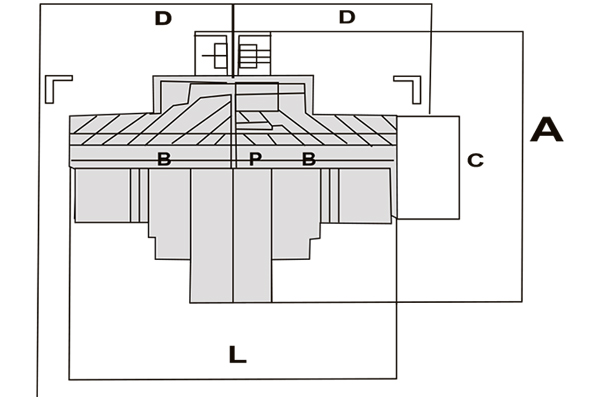

BVGD Coupling

|

TYPE BVGD

| Size | Kw at 100 rpm | Max. Speed | Bore | Dimensions Weight | Kg. V H |

|||||||||

| A | B | C | L | D | P | |||||||||

| z | x | Pilot | Max. | z | x | z | x | |||||||

| BVGD - 01 | 0.45 | 5800 | 3600 | 10 | 29 | 105 | 104 | 38.0 | 43 | 76 | 53 | 0.80 | 3 | 3 |

| BVGD - 02 | 0.70 | 5000 | 3350 | 12 | 38 | 120 | 120 | 38.0 | 55 | 76 | 53 | 0.80 | 4 | 4 |

| BVGD - 03 | 1.50 | 4500 | 3350 | 16 | 42 | 144 | 127 | 44.5 | 60 | 89 | 60 | 0.80 | 5 | 5 |

| BVGD - 04 | 2.20 | 3500 | 2600 | 16 | 58 | 172 | 159 | 51.0 | 85 | 102 | 60 | 0.80 | 9 | 8 |

| BVGD - 05 | 3.40 | 3300 | 2400 | 16 | 58 | 190 | 178 | 51.0 | 84 | 102 | 80 | 0.80 | 11 | 13 |

| BVGD - 07 | 4.90 | 3100 | 2200 | 16 | 65 | 197 | 190 | 57.0 | 95 | 114 | 80 | 0.80 | 16 | 17 |

| BVGD - 08 | 7.00 | 2600 | 1900 | 25 | 80 | 222 | 222 | 63.5 | 115 | 127 | 80 | 0.80 | 20 | 19 |

| BVGD - 09 | 9.40 | 2300 | 1700 | 25 | 95 | 254 | 245 | 70.0 | 140 | 140 | 81 | 0.80 | 27 | 27 |

| BVGD - 10 | 13.80 | 2000 | 1600 | 25 | 110 | 276 | 267 | 89.0 | 160 | 178 | 81 | 1.60 | 43 | 39 |

| BVGD - 11 | 26.50 | 1900 | 1500 | 38 | 104 | 295 | 324 | 102.0 | 153 | 204 | 129 | 1.60 | 54 | 47 |

| BVGD - 13 | 33.90 | 1800 | 1300 | 50 | 124 | 324 | 336 | 101.5 | 185 | 202 | 148 | 1.60 | 63 | 67 |

| BVGD - 14 | 48.90 | 1600 | 1300 | 50 | 124 | 336 | 381 | 101.5 | 180 | 202 | 148 | 1.60 | 72 | 74 |

| BVGD - 15 | 67.50 | 1400 | 1100 | 50 | 148 | 375 | 381 | 114.0 | 220 | 228 | 148 | 1.60 | 104 | 108 |

| BVGD - 17 | 93.60 | 1200 | 1000 | 50 | 170 | 425 | 425 | 127.0 | 250 | 254 | 148 | 1.60 | 149 | 149 |

| BVGD - 20 | 179.00 | 1200 | 800 | 75 | *157 | 432 | 501 | 140.0 | #236 | 280 | 180 | 3.20 | 180 | 234 |

| BVGD - 22 | 261.00 | 1100 | 700 | 85 | *173 | 492 | 552 | 152.5 | #260 | 304 | 180 | 3.20 | 216 | 318 |

| BVGD - 25 | 5.55 | 1200 | *** | 110 | 185 | 686 | *** | 178 | 285.7 | 356 | *** | 3.20 | 446 | *** |

| BVGD - 26 | 7.55 | 1050 | *** | 135 | 210 | 781 | *** | 203 | 324 | 406 | *** | 3.20 | 578 | *** |

| BVGD - 27 | 10.55 | 900 | *** | 145 | 242 | 876 | *** | 228 | 368 | 456 | *** | 6.35 | 910 | *** |

| BVGD - 28 | 17.55 | 800 | *** | 155 | 265 | 1015 | *** | 228 | 406 | 456 | *** | 6.35 | 1605 | *** |

Applications

- Cement mills: Crushers and grinding machines.

- Steel mills: Coilers, cold mills, hot mills etc.

- Paper mills: Calendar, couch roll, suction roll, dryer drives etc.

- Sugar mills: Cane carrier and leveler, cane knife and crusher.

- General: Agitators, Blowers, conveyors, cranes etc.